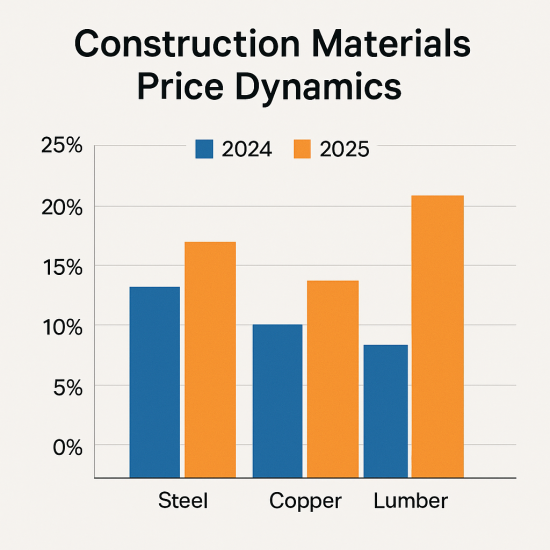

Why Are Construction Costs Still Climbing in 2025?: Inflation eased—but tariffs on steel, copper and lumber keep bids volatile.

Have you noticed that, despite falling inflation, your renovation or build quote seems to climb every time you check? The truth is, while general inflation ticked down in early 2025, tariffs on key materials—steel, copper, and lumber—are still squeezing budgets for contractors and homeowners alike. In this post, we’ll break down the real reasons costs remain high, show you how these price drivers translate into your bids, and share practical tactics—like value-engineering and early material buy-outs—that can help you lock in better pricing and stay on budget.

Main Material Price Drivers

- Tariffs on Steel and Copper

Since 2022, the U.S. has maintained tariffs of up to 25% on imported steel and 10% on copper products. Even though domestic producers have ramped up, supply can’t keep pace with demand, especially with big infrastructure projects using more metal. As a result, contractors are forced to pay premiums or build in risk buffers, which get passed down to homeowners. - Lumber Market Volatility

Lumber prices spiked during the pandemic due to mill shutdowns and then crashed in late 2023. However, Canadian lumber tariffs (averaging around 20%) remain in place for many contractors, so even as raw prices stabilized, those added duties keep costs roughly 15-20% above pre-pandemic levels. When you receive a quote, that $1 board might be $1.20 by the time it lands at the job site. - Transportation and Fuel Costs

Diesel and fuel prices rose sharply in late 2024 after OPEC+ output cuts. While they’ve eased slightly in Q1 2025, shipping costs for bulk materials—especially across longer distances—remain about 12% higher than 2022 levels. That extra on-road cost trickles down into every component of your build. - Labor Constraints and Subcontractor Margins

A nationwide skilled-labor shortage means electricians, plumbers, and masons can demand higher rates. Subcontractor margins often account for labor risk. When materials cost more or are harder to source, subs add contingency to their bids. That means your framing crew might charge 5-10% extra just to cover the risk of material price spikes mid-job.

Strategies to Control Costs

- Value-Engineering Without Sacrificing Quality

Value-engineering isn’t about choosing the cheapest tile; it’s about making smart design choices that cut costs but still meet your aesthetic and performance goals. For example:

- Opt for engineered lumber or laminated beams over solid timber. They’re often more structurally efficient and sometimes cheaper per strength unit.

- Choose a mid-range countertop material (like quartz) installed by a reputable fabricator instead of a high-end granite slab that can run 30-40% more.

- Simplify roof geometry—each hip or valley adds framing and labor hours. A basic gable roof design could shave thousands off your build cost without sacrificing curb appeal.

- Locking In Early Material Buy-Outs

When you sign a contract, you or your contractor can “buy out” long-lead items (like windows, trusses, or custom cabinets) at current prices instead of waiting. Even if your project kicks off in three months, pay a deposit now to secure pricing. If lumber costs climb another 10% next quarter, you won’t pay the difference. Just be sure to read payment terms carefully—look for refundable deposits or options to transfer to a vendor credit if plans change. - Bulk Purchasing and Consolidated Shipments

If your project is large enough (or you’re working with a contractor handling multiple jobs), negotiate bulk rates. Consolidate shipments to avoid multiple freight charges. Sometimes, working with neighboring builds or small developments can give you enough volume to qualify for discounted pricing. - Alternative Materials and Local Suppliers

With tariffs making imports pricey, explore regional mills and reclaimed-material suppliers. For instance, reclaimed hardwood flooring can run 15-25% cheaper than new hardwood, and local sawmills might offer better rates on framing lumber without the tariff markup. Check online marketplaces or local building salvage yards. - Transparent Bidding and Shared Risk

Ask your contractor for a “cost-plus” or “open-book” invoice method: you pay the actual cost of materials plus a fixed margin. That way, if lumber spikes mid-project, you see why. You can also include an escalation clause: if certain material costs rise beyond a threshold, both parties share the burden. This transparency often leads to trust and better decisions on material substitutions.

Real-World Example: Sarah’s Kitchen Renovation

Sarah wanted to gut her 1995 kitchen and install semi-custom cabinets, quartz countertops, and new hardwood flooring. Her initial quote in January 2025 was $45,000, but by March, her contractor’s material cost for cabinets rose 12% due to aluminum handle shortages (tied to copper price hikes). By April, flooring prices spiked 8% from rising transportation costs. Instead of paying the full bump, her contractor recommended:

- Switching to a locally manufactured cabinet line that used composite door faces—15% cheaper but virtually identical in look.

- Locking in a flooring buy-out in March, saving her 8% on hardwood.

- Sourcing a quartz slab from a domestic supplier, avoiding a 10% copper-based surcharge.

In the end, Sarah spent $47,000 instead of an expected $50,000. By leveraging alternatives and securing early buys, she avoided a $5,000 cost increase.

Key Takeaways for Homeowners

- Don’t assume “fixed-price” means fixed forever. Material markets can change quickly—ask about price lock options.

- Consider value-engineering as a chance to get creative—often, you’ll find options that look just as good but cost less.

- Shop around for local suppliers and secondary-market materials to dodge tariffs.

- Build strong communication with your contractor. The more transparency on material costs, the fewer surprises you’ll face.

Conclusion

Navigating the ongoing climb of construction costs in 2025 means understanding why your quotes keep rising—tariffs, transportation, and labor risk are the main culprits. But armed with strategies like value-engineering, early buy-outs, and smart sourcing, you can take control of your project budget. By staying proactive and transparent, you’ll build the home you want without letting ever-rising material costs derail your vision.